OEM cast magnesium heat sink

Basic Information:

|

Place of Origin: |

Zhengzhou China (Mainland) |

|

Brand Name: |

SinoMg |

|

Certification: |

ISO9001:2000. SGS |

|

Model Number: |

AZ91D |

|

Minimum Order Quantity: |

100 Piece |

|

Price: |

Negotiable |

|

Packaging Details: |

Carton |

|

Delivery Time: |

25-30 days |

|

Payment Terms: |

T/T, L/C, Western Union, MoneyGram, Paypal |

|

Supply Ability: |

1,000,000 Kilogram per month |

Detail Information

|

Product Name: |

Magnesium-based Heat Sink |

Model: |

AZ91D |

|

Material: |

Magnesium Alloys, Mag Alloys |

Application: |

Aviation, Electronic, Industrial, Chemical |

|

Standard: |

JIS,GB, DIN, BS, ASTM & AISI |

Purity: |

≥96% |

|

Alloy Or Not: |

Alloy |

Tolerance: |

+/-1%, +/-0.02MM |

|

Technology Process: |

Extrusion, Deburring, CNC Machining Checking & Packing |

Specification: |

As Per Customer's Drawing |

|

Process Service: |

Ending, Welding, Punching, Cutting & Machining |

Surface Treatment: |

Painting, Powder Coating, Polishing & Electroplating |

|

OEM: |

Available |

HS Code: |

8104902090 |

|

High Light: |

SGS 95% Magnesium Heat Sink, AZ91D Electronic Heatsink, 95% mg Heat Sink Aluminium Extrusion |

||

Product Description

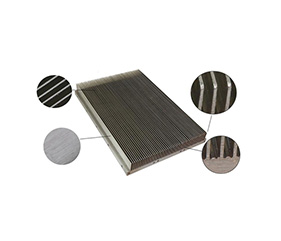

China Manufacturer Customize Extruded Magnesium Alloy Heat Sink AZ91D

Description

Heat sinks are thermally conductive components or devices that absorb and dissipate heat generated by electronic components. Heat sinks cool high-powered devices to prevent overheating. The reliability of electronic components is generally reduced by the square of an increase in temperature. For example, doubling the ambient temperature around a component renders the component 25% less reliable than at the lower temperature. Heat sinks are therefore essential in dissipating generated heat and improving component longevity.

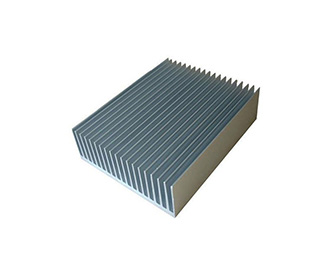

Specific strength: magnesium alloy is equivalent to aluminum alloy and steel, much higher than fiber reinforced plastics;

Wear resistance: the wear resistance of magnesium alloy is much higher than that of die-cast aluminum alloy A380;

Damping performance: magnesium alloy is 30 times higher than aluminum alloy;

Specification

Heat sinks are thermally conductive components or devices that absorb and dissipate heat generated by electronic components. Heat sinks cool high-powered devices to prevent overheating. The reliability of electronic components is generally reduced by the square of an increase in temperature.

|

Product Name |

Heatsink;Magnesium heat sink;Extruded heatsink;Heat sink extrusion |

|

Material |

AZ91D |

|

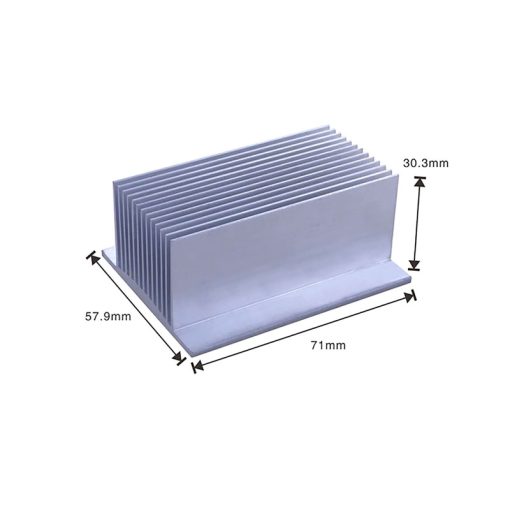

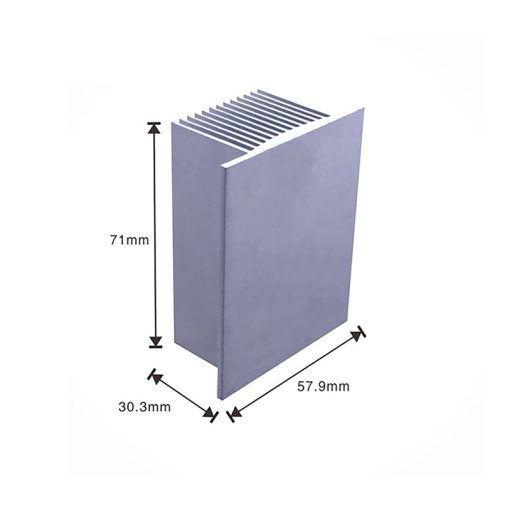

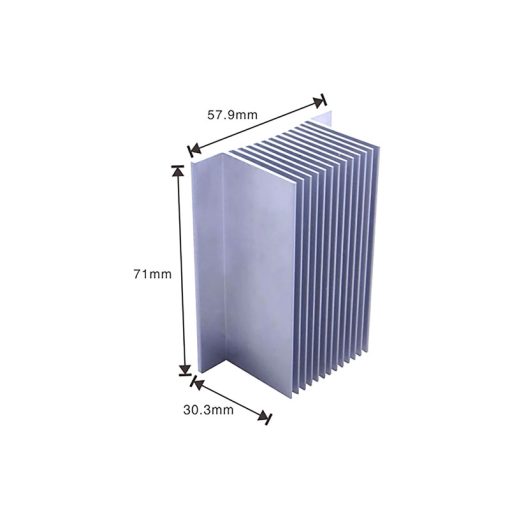

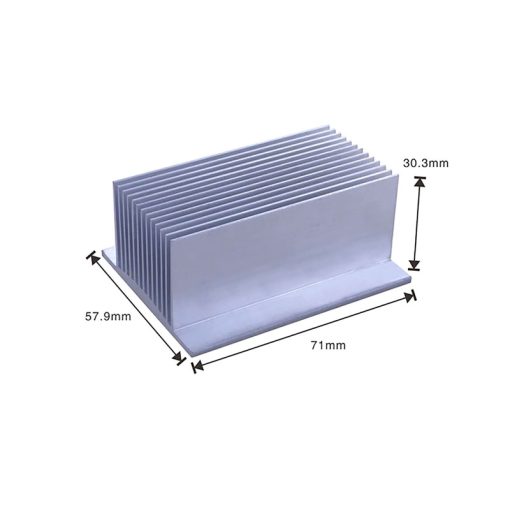

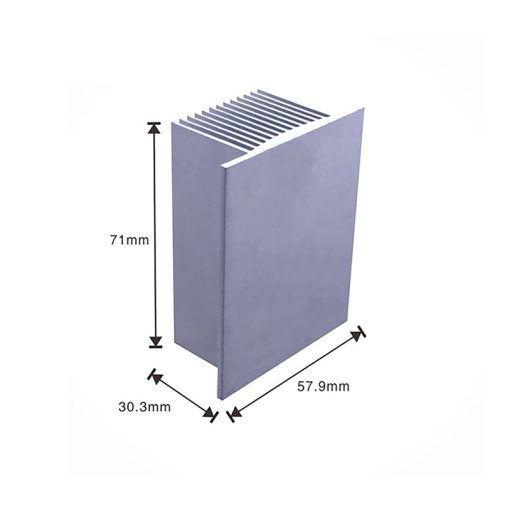

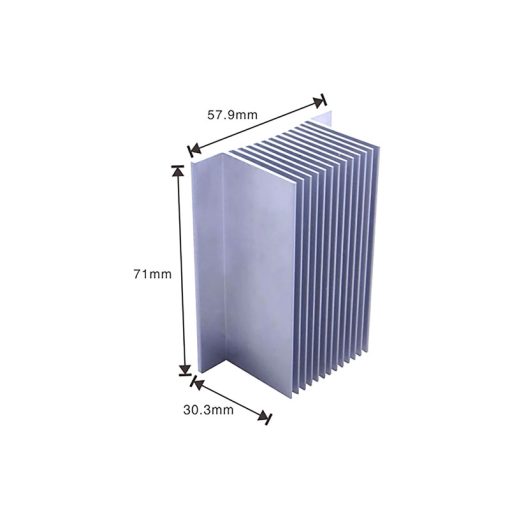

Detailed Size |

As per customers' design |

|

Max Aspect Ratio( Fin Height / Fin Gap) |

More than 20 times aspect ratio heatsink can be extruded by 800 Tons--6000 Tons extruding machines by most advanced technology |

|

Max Width |

Ultra wide extruded heatsink can be made by our unique friction welding technology |

|

Standard Mold Qty |

30,000+ sets standard molds in stock for your option,saving your R&D cost |

|

Sample Service |

Samples with differernt sizes are availabe for prototypes test within 1 week |

|

Production Process |

Profiles Extruding---Cutting---CNC Machining(Milling, Drilling,Tapping)---Deburring--- Cleaning--- Inspecting--Packing |

|

Surface Treatment |

Degreasing,(Black) Anodizing,Sand Blasting,Painting,Chromating and Laser marking |

|

Reference Standard |

GB/T 3190-2008,GB/T 14846-2008,ISO 2768 |

|

Experience |

More than 20 years professional manufacturing experience |

|

Application |

LED Lighting,Inverter,Welding Machine,Communication Device,Power Supply Equipment,Electronic Industry,Thermoelectric Coolers/Generator,IGBT/UPS Cooling Systems,etc. |

As the lightest structural material, magnesium alloy has low specific gravity (about 23% of steel and 64% of aluminum) and high specific strength and stiffness.Good thermal and electrical conductivity;With good electromagnetic shielding, damping, shock absorption, and cutting and die casting process performance.

SGS 95% Magnesium Heat Sink Aluminium Extrusion AZ91D Electronic Heatsink

-

1.What characteristics make a heatsink a good one?

A: High heatsink surface;Good aerodynamics;Good thermal transfer within the heatsink;Perfect flatness of the contact area;Good mounting method.

-

2.How long is your delivery time?

A:Generally it is 5-10 days if the heatsinks are in stock. or it is 30-40 days for mass production

-

3.Do you provide samples ?

A: Yes, we could offer paid sample for prototypes testing if there is stock.we have thousands of standard heatsinks with different sizes and shapes.

-

4.What is your terms of payment ?

A: Usually 100% payment before shipment. For regular customers,the terms can be nogotiated.