Magnesium alloy cast radiator

Basic Information:

|

Place of Origin: |

Zhengzhou China (Mainland) |

|

Brand Name: |

SinoMg |

|

Certification: |

ISO9001:2000. SGS |

|

Model Number: |

AZ91D |

|

Minimum Order Quantity: |

100 Piece |

|

Price: |

Negotiable |

|

Packaging Details: |

Carton |

|

Delivery Time: |

25-30 days |

|

Payment Terms: |

T/T, L/C, Western Union, MoneyGram, Paypal |

|

Supply Ability: |

1,000,000 Kilogram per month |

Detail Information

|

Item: |

Magnesium Heat Sink |

Model: |

AZ91D |

|

Material: |

Magnesium Alloy, Mg Alloy |

Applications: |

Aviation, Electronic,Industrial & Chemical |

|

Standard: |

JIS, GB, DIN,BS,ASTM,AISI |

Purity: |

≥96% |

|

Alloy Or Not: |

Alloy |

Tolerance: |

+/-1%,+/-0.02 MM |

|

Tech Process: |

Extrusion, Deburring, CNC Machining Checking & Packing |

Specification: |

3D Drawings |

|

Process Service: |

Ending, Welding, Punching,Cutting & Machining |

Surface Complete: |

Painting, Powder Coating, Polishing & Electroplating |

|

OEM/ODM: |

Available |

HS Code: |

8104902090 |

|

High Light: |

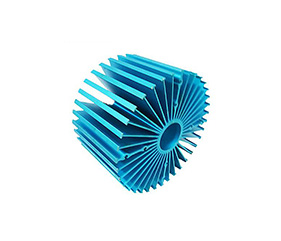

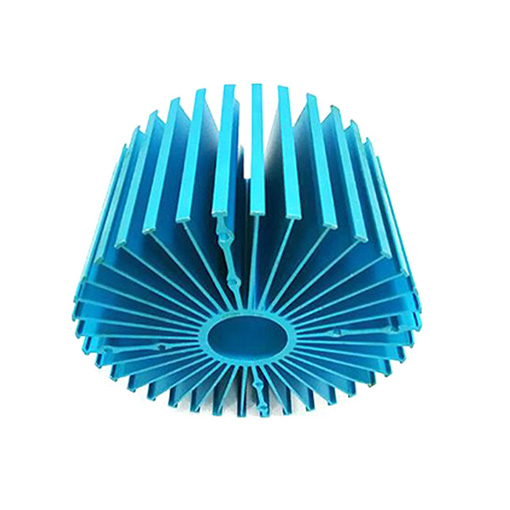

Magnesium Round Extruded Aluminum Heatsink, Round Extruded Aluminum Heatsink AZ91D, ASTM AISI Magnesium Heat Sink |

||

Product Description

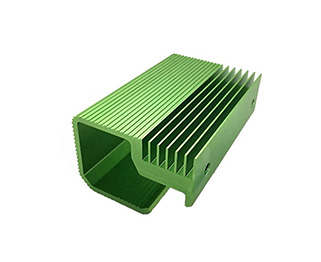

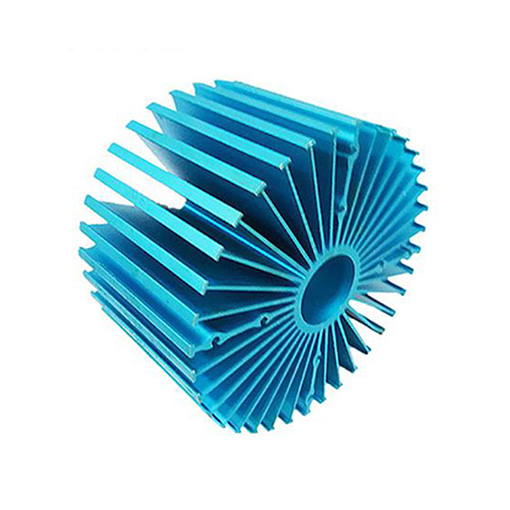

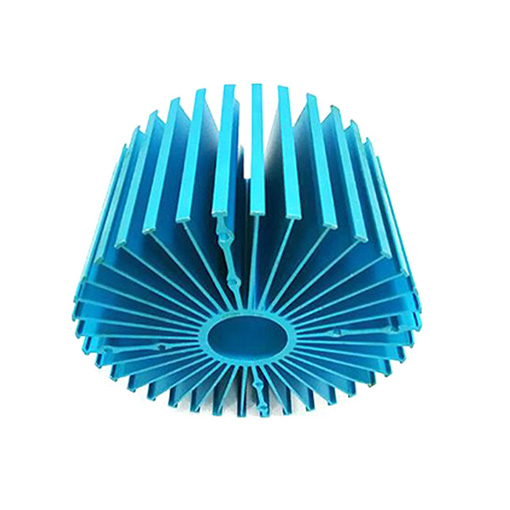

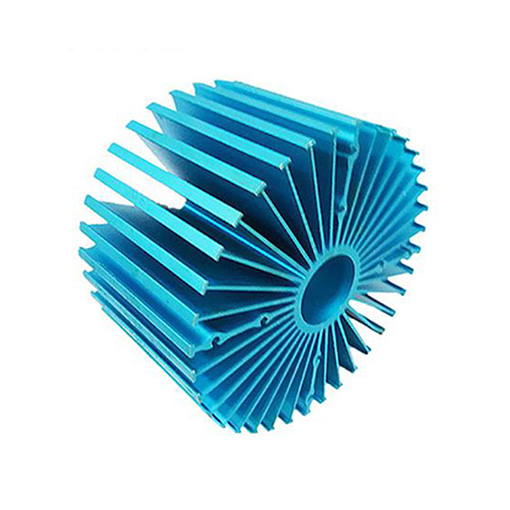

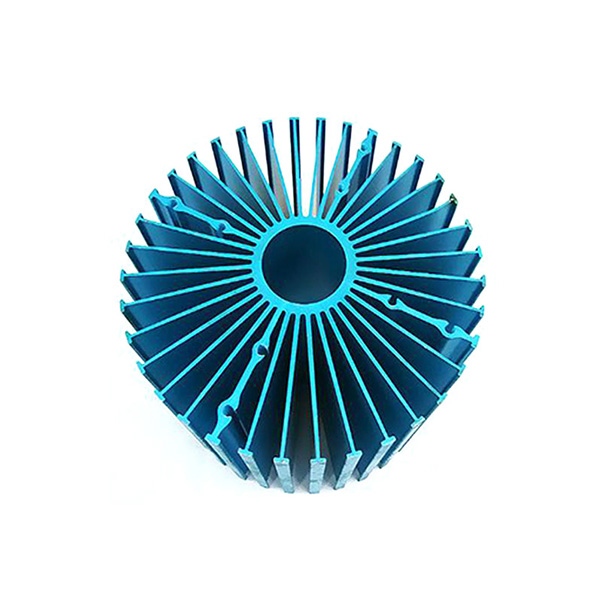

OEM/ODM Manufacturer Magnesium Extrusion Heat Sink AZ91D by Die Casting

Description

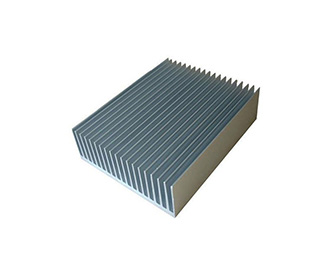

Heat sinks are thermally conductive components or devices that absorb and dissipate heat generated by electronic components. Heat sinks cool high-powered devices to prevent overheating. The reliability of electronic components is generally reduced by the square of an increase in temperature. For example, doubling the ambient temperature around a component renders the component 25% less reliable than at the lower temperature. Heat sinks are therefore essential in dissipating generated heat and improving component longevity.

Moreover, the performance of magnesium alloy die castings is excellent, and the effect of substituting steel, aluminum alloy, plastic and other parts under normal conditions of use is very good. While realizing the light weight of the product, it also enables the product to have excellent special functions, and after the magnesium alloy die casting is scrapped, it can be directly recycled and reused, which meets the requirements of environmental protection. Therefore, magnesium alloys with excellent comprehensive properties are known as the "21st Century Metal" and are widely used in automobiles, computers, communications and other broad fields.

Magnesium alloy is the lightest metal structural material, its density is 1.75-1.90s/cm3; its specific strength is higher than aluminum alloy and steel, and slightly lower than the highest specific strength fiber reinforced plastics; its machinability is excellent, easy to process and The processing cost is low, and the processing energy is only 70% of aluminum alloy; its corrosion resistance is much better than that of low-carbon steel, which has exceeded the die-cast aluminum alloy A380; its vibration damping and electromagnetic shielding properties are far better than aluminum alloy.

Specification

Heat sinks are thermally conductive components or devices that absorb and dissipate heat generated by electronic components. Heat sinks cool high-powered devices to prevent overheating.

|

Product Name |

Heatsink; Magnesium heat sink; Extruded heatsink; Heat sink extrusion |

|

Material |

AZ91D |

|

Detailed Size |

As per customers' design |

|

Max Aspect Ratio( Fin Height / Fin Gap) |

More than 20 times aspect ratio heatsink can be extruded by 800 Tons--6000 Tons extruding machines by most advanced technology |

|

Max Width |

Ultra wide extruded heatsink can be made by our unique friction welding technology |

|

Standard Mold Qty |

30,000+ sets standard molds in stock for your option,saving your R&D cost |

|

Sample Service |

Samples with differernt sizes are availabe for prototypes test within 1 week |

|

Production Process |

Profiles Extruding---Cutting---CNC Machining(Milling, Drilling,Tapping)---Deburring--- Cleaning--- Inspecting--Packing |

|

Surface Treatment |

Degreasing,(Black) Anodizing,Sand Blasting,Painting,Chromating and Laser marking |

|

Reference Standard |

GB/T 3190-2008, GB/T 14846-2008, ISO 2768 |

|

Experience |

More than 20 years professional manufacturing experience |

|

Application |

LED Lighting,Inverter,Welding Machine,Communication Device,Power Supply Equipment,Electronic Industry,Thermoelectric Coolers/Generator,IGBT/UPS Cooling Systems,etc. |

Magnesium (Mg), the 12th element on the periodic table, is a basic earth metal, ahead of aluminum (AL).Magnesium is one of the most abundant light metallic elements on earth, and is widely found in magnesite (magnesium carbonate), dolomite (calcium magnesium carbonate) and carnallite (magnesium potassium chloride hydrate).

Good heat transfer: Although the thermal conductivity of magnesium alloy is not as good as that of aluminum alloy, it is dozens of times higher than that of plastic. Therefore, magnesium alloy used in electrical products can effectively dissipate internal heat to the outside.

Application range: Magnesium alloy is used in the casing and heat dissipation parts of computers and projectors that generate high temperatures inside. The use of magnesium alloy on the casing of the TV can achieve no heat dissipation holes.

ASTM AISI Magnesium Round Extruded Aluminum Heatsink AZ91D OEM ODM

-

1.What characteristics make a heatsink a good one?

A: High heatsink surface;Good aerodynamics;Good thermal transfer within the heatsink;Perfect flatness of the contact area;Good mounting method.

-

2.How long is your delivery time?

A:Generally it is 5-10 days if the heatsinks are in stock. or it is 30-40 days for mass production

-

3.Do you provide samples ?

A: Yes, we could offer paid sample for prototypes testing if there is stock.we have thousands of standard heatsinks with different sizes and shapes.

-

4.What is your terms of payment ?

A: Usually 100% payment before shipment. For regular customers,the terms can be nogotiated.