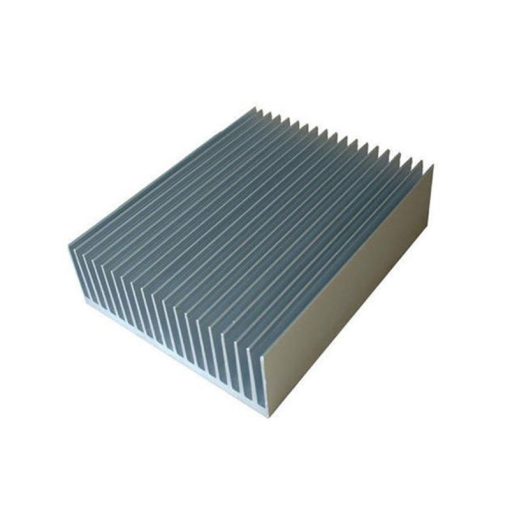

High precision AZ91D heat sink

Basic Information:

|

Place of Origin: |

Zhengzhou China (Mainland) |

|

Brand Name: |

SinoMg |

|

Certification: |

ISO9001:2000. SGS |

|

Model Number: |

AZ31B |

|

Minimum Order Quantity: |

100 Piece |

|

Price: |

Negotiable |

|

Packaging Details: |

Carton |

|

Delivery Time: |

25-30 days |

|

Payment Terms: |

T/T, L/C, Western Union, MoneyGram, Paypal |

|

Supply Ability: |

1,000,000 Kilogram per month |

Detail Information

|

Product Name: |

Magnesium-based Heat Sink |

Model: |

AZ31B |

|

Material: |

Magnesium Alloys, Mag Alloys |

Application: |

Aviation, Electronic, Industrial, Chemical |

|

Standard: |

JIS,GB, DIN, BS, ASTM & AISI |

Purity: |

≥96% |

|

Alloy Or Not: |

Alloy |

Tolerance: |

+/-1%, +/-0.02MM |

|

Technology Process: |

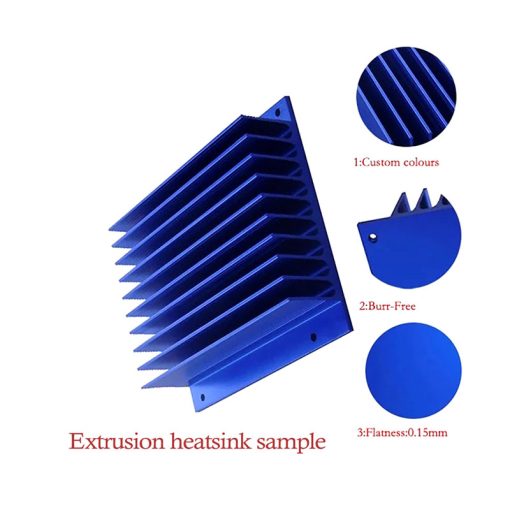

Extrusion, Deburring, CNC Machining Checking & Packing |

Specification: |

As Per Customer's Drawing |

|

Process Service: |

Ending, Welding, Punching, Cutting & Machining |

Surface Treatment: |

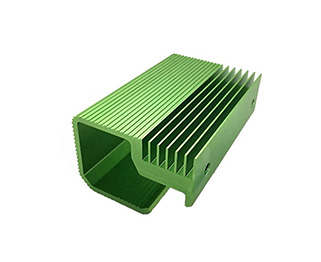

Painting, Powder Coating, Polishing & Electroplating |

|

OEM: |

Available |

HS Code: |

8104902090 |

|

High Light: |

High Precision Magnesium Heat Sink, Magnesium Heat Sink AZ31B, AZ31B Power Supply Heat Sink |

||

Product Description

High Precision Magnesium Alloy Heat Sink AZ31B For Power Electronic & Semiconductor

Description

Heat sinks are thermally conductive components or devices that absorb and dissipate heat generated by electronic components. Heat sinks cool high-powered devices to prevent overheating. The reliability of electronic components is generally reduced by the square of an increase in temperature. For example, doubling the ambient temperature around a component renders the component 25% less reliable than at the lower temperature. Heat sinks are therefore essential in dissipating generated heat and improving component longevity.

Specific strength: magnesium alloy is equivalent to aluminum alloy and steel, much higher than fiber reinforced plastics;

Wear resistance: the wear resistance of magnesium alloy is much higher than that of die-cast aluminum alloy A380;

Damping performance: magnesium alloy is 30 times higher than aluminum alloy;

Specification

Heat sinks are thermally conductive components or devices that absorb and dissipate heat generated by electronic components. Heat sinks cool high-powered devices to prevent overheating. The reliability of electronic components is generally reduced by the square of an increase in temperature.

|

Product Name |

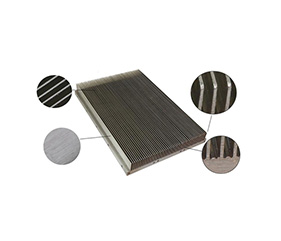

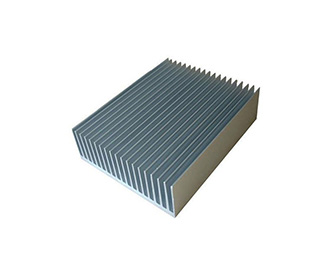

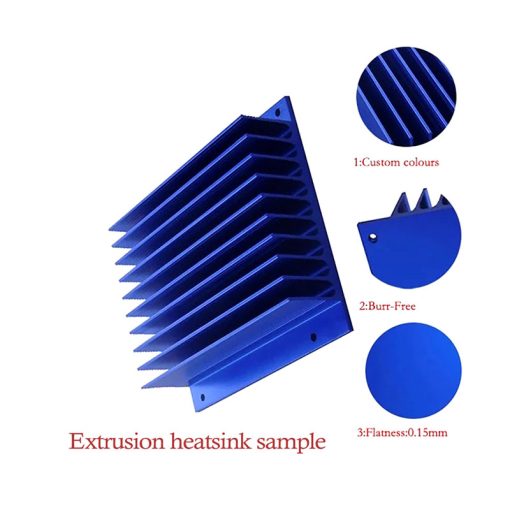

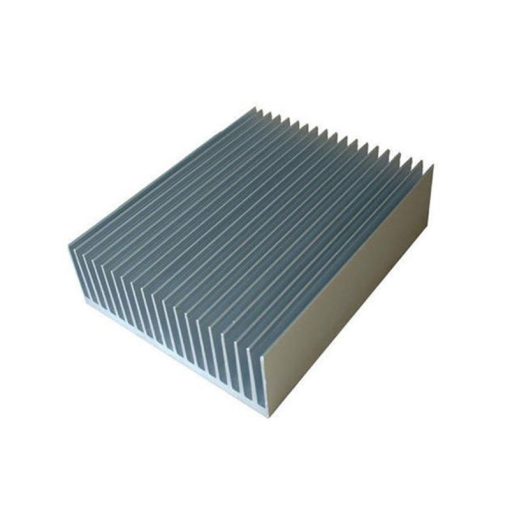

Heatsink;Magnesium heat sink;Extruded heatsink;Heat sink extrusion |

|

Material |

AZ91B |

|

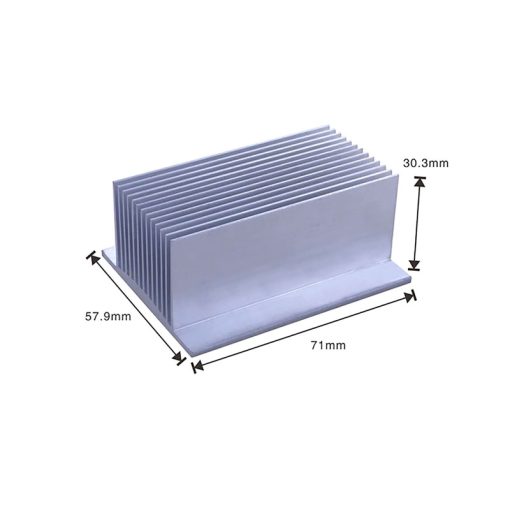

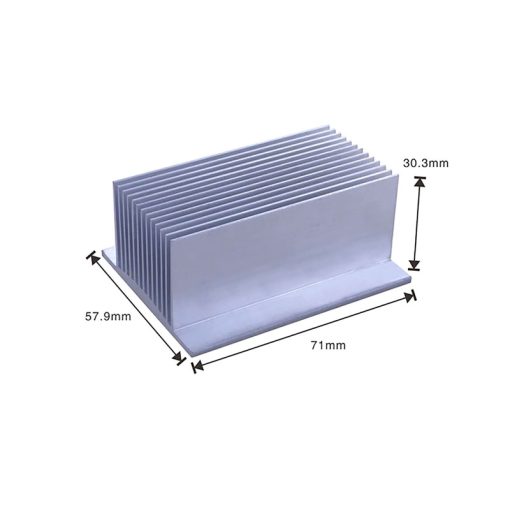

Detailed Size |

As per customers' design |

|

Max Aspect Ratio( Fin Height / Fin Gap) |

More than 20 times aspect ratio heatsink can be extruded by 800 Tons--6000 Tons extruding machines by most advanced technology |

|

Max Width |

Ultra wide extruded heatsink can be made by our unique friction welding technology |

|

Standard Mold Qty |

30,000+ sets standard molds in stock for your option,saving your R&D cost |

|

Sample Service |

Samples with differernt sizes are availabe for prototypes test within 1 week |

|

Production Process |

Profiles Extruding---Cutting---CNC Machining(Milling, Drilling,Tapping)---Deburring--- Cleaning--- Inspecting--Packing |

|

Surface Treatment |

Degreasing,(Black) Anodizing,Sand Blasting,Painting,Chromating and Laser marking |

|

Reference Standard |

GB/T 3190-2008,GB/T 14846-2008,ISO 2768 |

|

Experience |

More than 20 years professional manufacturing experience |

|

Application |

LED Lighting,Inverter,Welding Machine,Communication Device,Power Supply Equipment,Electronic Industry,Thermoelectric Coolers/Generator,IGBT/UPS Cooling Systems,etc. |

As the lightest structural material, magnesium alloy has low specific gravity (about 23% of steel and 64% of aluminum) and high specific strength and stiffness.Good thermal and electrical conductivity;With good electromagnetic shielding, damping, shock absorption, and cutting and die casting process performance.

High Precision Magnesium Heat Sink AZ31B Power Supply Heat Sink

-

1.What characteristics make a heatsink a good one?

A: High heatsink surface;Good aerodynamics;Good thermal transfer within the heatsink;Perfect flatness of the contact area;Good mounting method.

-

2.How long is your delivery time?

A:Generally it is 5-10 days if the heatsinks are in stock. or it is 30-40 days for mass production

-

3.Do you provide samples ?

A: Yes, we could offer paid sample for prototypes testing if there is stock.we have thousands of standard heatsinks with different sizes and shapes.

-

4.What is your terms of payment ?

A: Usually 100% payment before shipment. For regular customers,the terms can be nogotiated.