-

Magnesium plate:

Magnesium alloy is an alloy composed of magnesium and other elements.

It is characterized by low density (about 1.8g/cm3 magnesium alloy), high specific strength, large specific elastic modulus, good heat dissipation, good shock absorption, greater impact load bearing capacity than aluminum alloy, and good corrosion resistance to organic matter and alkali.

The main alloy elements are aluminum, zinc, manganese, cerium, thorium and a small amount of zirconium or cadmium. At present, magnesium aluminum alloy is the most widely used, followed by magnesium manganese alloy and magnesium zinc zirconium alloy.

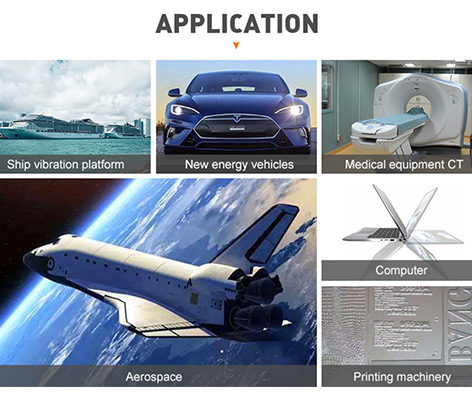

It is mainly used in aviation, aerospace, transportation, chemical industry, rocket and other industrial departments.

-

Magnesium Sacrificial Anode:

Magnesium alloy anode has high potential and is often used for cathodic protection of buried structures.

It is mainly used for anti-corrosion protection of underground and fresh water oil and gas transmission, water supply and drainage pipelines, underground cables, chemical industry, communication, harbor, ship, reservoir gate and other projects.For example, oil and gas pipelines, storage tanks, hot water exchangers, condensers, etc

-

Magnesium welding wire:

Magnesium alloy welding wire is used for all kinds of forging magnesium alloys and casting magnesium alloys. It is widely used in the welding of optical instruments, aerospace, auto parts, civil magnesium products and handicrafts.

It is a special magnesium alloy welding wire for welding and repairing magnesium alloy fractures, cracks, trachoma and pores