High strength extruded Mg tube

Basic Information:

|

Place of Origin: |

Zhengzhou China (Mainland) |

|

Brand Name: |

SinoMg |

|

Certification: |

ISO9001:2000. SGS |

|

Model Number: |

AZ31B AZ61 AZ91D WE43 ZK61M |

|

Minimum Order Quantity: |

100 Kilogram |

|

Price: |

Negotiable |

|

Packaging Details: |

Wooden Case |

|

Delivery Time: |

10-15 days |

|

Payment Terms: |

T/T, L/C, Western Union, MoneyGram, Paypal |

|

Supply Ability: |

1,000 Ton per year |

Detail Information

|

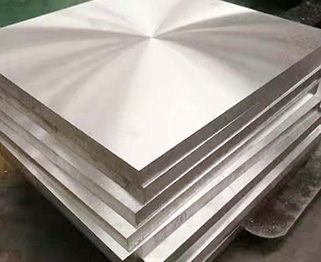

Product Name: |

Magnesium Alloy Round Tube |

Materials: |

Magnesium Alloy, Mag Alloy |

|

Formula: |

Mg. |

Purity: |

>95% |

|

Chemical: |

Mg, Zn, Al, Mn, Fe |

Diameter: |

0.5 - 300 MM |

|

Length: |

100 - 2000 MM |

Applicaiton: |

Automobile Industry, Metallurgy,Aerospace, 3C Product |

|

Type: |

Tube & Pipe |

Color: |

Silvery White |

|

Surface Treatment: |

Polishing |

Surfaces: |

Smoothing |

|

Standard: |

JIS,GB, DIN, BS, ASTM & AISI |

Shape: |

Round, Rod |

|

OEM/ODM: |

Yes |

HS Code: |

81049020 |

|

High Light: |

Seamless AZ61 Magnesium Alloy Pipe , High Strength AZ61 Magnesium Alloy Pipe , ZK61M Alloy Round Tube |

||

Product Description

Professional Manufacturer Magnesium Alloy Round Pipe for Aircraft Parts

Why SINOMAGNESIUM Product?

Worldwide standards of ASTM, AMS, BS, MG-P-62, etc..

Purity - Mg ≥ 99.90%, 99.95%

Sample offered

Direct factory from Henan province in China, with strict quality system

Prompt airway delivery and oversea shipment

Professional and great patient customer service after puchasement

Physical Properties

Density: 1.78;

Coefficient of thermal expansion: 26.8 x 10-6K-1

Specific heat: 1040 Jkg-1k-1

Thermal conductivity: 76.9Wm-1k-1

Electrical resistivity: 92nΩm

Modulus of elasticity: 45 x 109Pa;

Poissons ratio: 0.35;

Melting range: 566 - 632°C

Magnesium alloy is the lightest metal structural material, its density is 1.75-1.90s/cm3; its specific strength is higher than aluminum alloy and steel, and slightly lower than the highest specific strength fiber reinforced plastics; its machinability is excellent, easy to process and The processing cost is low, and the processing energy is only 70% of aluminum alloy; its corrosion resistance is much better than that of low-carbon steel, which has exceeded the die-cast aluminum alloy A380; its vibration damping and electromagnetic shielding properties are far better than aluminum alloy.

Why Magnesium?

* Lightest structural metal-33% lighter than aluminum

* High specific strength

* Better machine-ability than aluminum

* Excellent for complex shapes and tight tolerances

* Better shock absorption and dent resistance

Magnesium alloys are well-known for being the lightest structural alloys. They are made of magnesium, the lightest structural metal, mixed with other metal elements to improve the physical properties. These elements include manganese, aluminium, zinc, silicon, copper, zirconium, and rare-earth metals; Some of magnesium's favourable properties include low specific gravity and a high strength-to-weight ratio. As a result, the material lends itself to a range of automotive, aerospace, industrial, electronic, biomedical, and commercial applications.

Specification

The performance of magnesium alloy die castings is excellent, and the effect of substituting steel, aluminum alloy, plastic and other parts under normal conditions of use is very good. While realizing the light weight of the product, it also enables the product to have excellent special functions, and after the magnesium alloy die casting is scrapped, it can be directly recycled and reused, which meets the requirements of environmental protection. Therefore, magnesium alloys with excellent comprehensive properties are known as the "21st Century Metal" and are widely used in automobiles, computers, communications and other broad fields.

| Alloy | Thickness(mm) | Tensile strength Rm(N/mm²) | Yield strength Rp0.2 (N/mm²) | Elongation (A%) 50mm |

| AZ31B | 0.3-3.00 | 260 | 170 | 24 |

| 3.00-10.00 | 230 | 140 | 18 | |

| M2M | 0.80-3.00 | 190 | 110 | 6 |

| 3.00-5.00 | 180 | 100 | 5 | |

| 5.0-10.00 | 170 | 90 | 5 | |

| AZ40M | 0.50-3.00 | 280 | 180 | 17 |

| 3.00-5.00 | 260 | 160 | 14 | |

| AZ41M | 0.80-3.00 | 290 | 190 | 17 |

| 3.00-5.00 | 270 | 170 | 17 | |

| ME20M | 0.80-3.00 | 250 | 170 | 21 |

| 3.00-10.00 | 220 | 140 | 15 |

| Extruded Magnesium Alloy Product List | ||||||||

| Type | Size(mm) | Actual Size (mm) | Remark | Type | Size(mm) | Actual Size (mm) | Remark | |

| Wire Rod | Φ4 | Φ4 | Round Tubing | Φ22*2 | Φ21.9*2.1 | |||

| Φ5 | Φ4.9 | Φ22*3 | ||||||

| Φ6 | Φ5.92 | Φ25*2 | Φ24.9*2 | |||||

| Φ8 | Φ8.04 | Φ25*3 | ||||||

| Φ11 | Φ10.9 | Φ28*3 | ||||||

| Anode Bar | Steel Core Dia.Φ2 | S=20 | S=19.7 | Φ29*2 | Φ29.18*2 | |||

| 13*14 | 12.6*33.6 | Φ32*2 | Φ32.2*2 | |||||

| Steel Core Dia.Φ3.2~3.5 | Φ14 | Φ13.94 | Φ45*2 | Φ44.5*2 | ||||

| Φ50*2.5 | Φ49.96*2.5 | |||||||

| Φ16 | Φ15.7 | Φ88*7.5 | ||||||

| Φ16.04 | ||||||||

| Φ16.6 | ||||||||

| Φ17 | Φ17.4 | Square Tubing | 20*20*2 | 19.7*19.7*2 | ||||

| Φ17.6 | 25*25*2.5 | 25*25*2.5 | ||||||

| Φ18 | Φ17.8 | 45*26*(3*2) | 45*26*(3.3*2) | |||||

| Φ18 | 50*30*2.5 | 49.7*29.8*2.5 | ||||||

| Φ19 | Φ18.7 | |||||||

| Φ18.6 | ||||||||

| Φ19.1 | ||||||||

| Φ20 | Φ19.8 | Plates | 25*5 | 24.7*24.7 | ||||

| Φ20.6 | 50*5 | 49.5*4.7 | ||||||

| Φ21 | Φ20.8 | 75*4 | 75.1*3.9 | |||||

| Φ21.3 | 80*1.6 | 79*1.65 | ||||||

| Φ22 | Φ21.8 | 80*2 | ||||||

| 90*1.4 | 89.7*1.35 | |||||||

| Φ23 | Φ22.6 | 100*1.2 | 100*1.15 | |||||

| Φ22.8 | 100*2 | 99.8*1.9 | ||||||

| Φ23.5 | ||||||||

| Φ26 | Φ25.9 | |||||||

| Φ26.2 | ||||||||

| Φ33 | Φ32.6 | Section Bar | 30*10*2.5 | L shape | ||||

| Φ33.3 | 45*23*2.5 | |||||||

| Ribbon | 9.5*19 | 9.4*18.8 | 50*25*2.5 | |||||

| Steel Core Dia.Φ5.3 | Φ18 | Φ17.95 | 96.5*35*3 | |||||

| Φ19 | Φ18.7 | |||||||

| Φ20 | Φ19.8 | 10*10*1.8 | ||||||

| Φ21 | Φ20.8 | 15*15*2 | ||||||

| Alloy Bar | Φ19 | Φ18.8 | ||||||

| Φ21 | Φ20.8 | 16*26 | Penknife use material | |||||

| Φ22 | 13*78 | Cooling fin | ||||||

| Φ25 | Φ24.8 | 25*25*2.5 | 25*25*2.5 | Concave shape | ||||

| Φ26 | Φ26.3 | 50*50*50*2.5 | 49.1*49.1*49.1*2.5 | Triangle | ||||

| Φ28 | Φ27.75 | 50*25*2.5 | Semi-circle | |||||

| Φ40 | Φ39.9 | 45*13*2 | Iformation | |||||

| Φ50 | Φ49.74 | |||||||

| Φ60 | Φ59.5 | |||||||

| Re: We can also produce them as per your datas & drawings | ||||||||

Payment

Payment terms - 30% in desposit. We can accept T/T, L/C if you need

1.Magnesium and magnesium alloy as a green environment protection industry material, widely used not only instrument produce and military affairs industry, but also making magnesium alloy, used as reducer, deoxidizer, alterative in producing some alloy. 2.Magnesium is a important material in avigation industry, magnesium alloy is widely used in making airplane, engine and other parts, it is also used in making optics instrument. 3.As a strong reducer, it still used in producing Titanium, Zirconium, Beryllium, Uranium. 4.Purity magnesium has a week intension, but magnesium alloy is a well light structural material, widely used in space technic, aviation, automobile and appearance bearing and other industry department.

High Strength Seamless AZ61 Magnesium Alloy Pipe ZK61M Alloy Round Tube

-

1.How long i can get the feedback after we sent the enquiry?

A: We will reply you within 12 hours in working day.

-

2.How can I get some samples?

A:We are pleased to offer you sample, the delivery time is about 4-7 days.

-

3.Are you a factory?

A: Yes. We are. We have specialized in this field over 10 Year.

-

4.Where is your factory located?

A: Our factory is located in the China magnesium base Henan Province. You are welcome to visite us.

-

5.What is the delivery time?

A: 15 days normally, detail delivery date should be decided according to production season and order quantity.