Cast magnesium bracelet anode

Basic Information:

|

Place of Origin: |

Zhengzhou China (Mainland) |

|

Brand Name: |

SinoMg |

|

Certification: |

ISO9001:2000. SGS |

|

Model Number: |

M69208 |

|

Minimum Order Quantity: |

20 Kilogram |

|

Price: |

Negotiable |

|

Packaging Details: |

Wooden Case |

|

Delivery Time: |

10-15 Days |

|

Payment Terms: |

T/T, L/C, Western Union, MoneyGram, Paypal |

|

Supply Ability: |

100,000 Piece per Month |

Detail Information

|

Produce Name: |

Magnesium Anode |

Model: |

M69208 |

|

Material: |

Magnesium Alloy |

Purity: |

>98% |

|

Shape: |

Round |

Application: |

Aviation, Electronics, Industrial, Medical, Chemical |

|

Thickness: |

0.5-300MM |

Width: |

500MM |

|

Standard: |

JIS, GB, DIN, BS, ASTM, AISI |

Enviroment: |

Sea Water, Fresh Water |

|

Feature: |

Water Heater |

Color: |

Silver White |

|

Surface: |

Bright |

Sample: |

Free |

|

HS Code: |

8104300010 |

OEM/O DM: |

Available |

| High Light: |

AZ63 Magnesium Sacrificial Anode, 97% Pure Magnesium Anode Rod, OEM Magnesium Sacrificial Anode |

||

Product Description

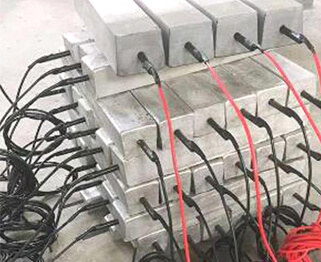

Cast Magnesium Alloy Bracelet Sacrificial Anode for Water Tank

Description

The use of magnesium sacrificial anodes for cathodic protection is an effective method to prevent metal corrosion. Magnesium alloy sacrificial anodes have the following characteristics: good corrosion resistance, no external DC power supply, automatic operation after installation, no maintenance, and less floor space , the project cost is low, and there is no interference with the external environment. Magnesium sacrificial anodes are widely used in petroleum pipelines, natural gas, gas pipelines and storage tank; port, ship, subsea pipeline, drilling platform; airport, parking lot, bridge, power plant, municipal construction, water treatment plant, petrochemical plant, smelter, corrosion protection of gas station, water heater, heat exchanger, evaporator, boiler and other equipment.

The pre-packaged magnesium alloy sacrificial anode body is mainly composed of a magnesium alloy sacrificial anode, a special heat shrinkable sleeve, and a cable. The anode body adopts a packing material with the required composition installed around the magnesium anode body. The pre-packaged magnesium alloy sacrificial anode was developed to simplify the rapid on-site construction procedure. The original operation on the construction site is completed in the factory, which effectively guarantees the construction and installation quality of the magnesium anode bed.

The distance between the sacrificial anode (magnesium anode) groups on the pipeline is 1 to 2 groups/km for long-distance pipelines, and 200 to 300 groups are appropriate for urban pipelines and internal pipeline networks.

Specification

Type: AZ31B, ZK61M, AZ80A, AZ91D, M2M, ME20M, AZ40

Specification: Casting round bar billet(Φ3-160*3000)

Remarks: According to the requirements of sawing and heat treatment

UK Standard ZK60 WE43 Magnesium Metal Plate Small Modulus Of Elasticity

|

Product Name: |

Magnesium-based Sacrificial Anode |

|

Material |

Magnesium alloy AZ31 AZ61 AZ91 AZ92 ZK61 |

|

Differnet Kinds |

Casting rod, Extruded rod, Rod with steel cap, Flexible anode rod |

|

Chemical Composition |

Al:2.5-3.5%, Zn:0.6-1.4%,Mn:0.2-1.0%,Fe:0.005%max,, Cu:0.01%max,Ni:0.001%max,Si:0.1%max, Other:0.3%max,Mg:Balance |

|

Property |

Open-circuit voltage: 1.5-1.55V Close-circuit voltage:1.45-1.50V Actual capacitance: 1.105A.h/g Current efficiency: 50% min |

|

Steel Cap |

stainless steel, galvannized, in black, coppper etc. |

|

Application |

It mainly used in water heater,boiler,heat exchanger,water tank,etc. It can softing water,de-dirt residual,ensure water sanitation,water scale inhibition,protect inner tank,extend service life,etc. |

|

Feature |

The extruded anode rod can be with or without steel core,can be with steel cap or only with screw;the size of cap/screw can be customilized by your specific requirements. Mainly different kinds of steel cap and screw available. |

Chemical Composition

High strength, heat resistant rare earth- magnesium alloy die castings set by national standard, ASTM, EN standard and autonomous development, such as steering wheel skeleton, the tank pan, power tools housing, electric wheel hub, 3C product shell and skeleton etc. The mechanical properties of the products are excellent and the microstructure of the products is homogeneous.

| Alloy Element | Type | Chemical Composition% | Other elements b | |||||||||||

| Mg | Al | Zn | Mn | Ce | Zr | Si | Fe | Ca | Cu | Ni | Be | Sub-total | ||

| MgAlZn | AZ31B | Balance | 2.5-3.5 | 0.6-1.4 | 0.1-0.2 | --- | --- | ≤0.08 | ≤0.003 | ≤0.04 | ≤0.01 | ≤0.001 | --- | ≤0.05 |

| AZ40M | Balance | 3.0-4.0 | 0.2-0.8 | 0.15-0.5 | --- | --- | ≤0.10 | ≤0.05 | --- | ≤0.05 | ≤0.005 | ≤0.01 | ≤0.01 | |

| AZ80A | Balance | 7.8-9.2 | 0.2-0.8 | 0.12-0.5 | --- | --- | ≤0.10 | ≤0.005 | --- | ≤0.05 | ≤0.005 | --- | --- | |

| AZ91D | Balance | 8.5-9.5 | 0.45-0.9 | 0.17-0.4 | --- | --- | ≤0.08 | ≤0.004 | --- | ≤0.025 | ≤0.001 | 0.0005- | ≤0.01 | |

| 0.003 | ||||||||||||||

| MgMn | M2M | Balance | ≤0.20 | ≤0.30 | 1.3-2.5 | --- | --- | ≤0.10 | ≤0.05 | --- | ≤0.05 | ≤0.007 | ≤0.01 | ≤0.01 |

| MgZnZr | ZK61M | Balance | ≤0.05 | 5.0-6.0 | ≤0.10 | --- | 0.3-0.9 | ≤0.05 | ≤0.05 | --- | ≤0.05 | ≤0.005 | ≤0.01 | ≤0.01 |

| MgMnRe | ME20M | Balance | ≤0.20 | ≤0.30 | 1.32-2.2 | 0.15-0.35 | --- | ≤0.10 | ≤0.05 | --- | ≤0.05 | ≤0.007 | ≤0.01 | ≤0.01 |

Application

1. Transportation

Seat frame, armrest, small table panel, pedal, in-built profiles, driving frame, sleeper frame work, dashboard frame work etc.

2. Electronics

Magnesium alloys have excellent thin wall casting performance. They wall thickness of magnesium alloy die castings can reach 0.6-1.0mm, and the die castings can remain certain strength, stiffness and impact resistance. These performances are very consistent with development demand of lightweight, thin short and small for laptop. Mobile phone, digital camera, that makes the application of magnesium alloy grow sustainably.

3. Aerospace industry

Engine shell, parts. Skin and cabin, frame, holder, wingtip, aileron, fuel tank, gearbox, airscrew, seat, undercarriage, all kinds of shell, siding, clapboard etc.

4. Military industry

Panzer tank vehicle, torpedo, guided missile, aircraft / spacecraft, military electronic equipment, military statellite.

5. Medical industry

Medical device and implant material.

Our Advantages

Corrosion protection

Protect water heater, water containers of steel structure

Protect the gas pipeline in-home service polarization high resistance electrolytes (soil and water in the steel structure)

Cast Magnesium Alloy Bracelet Sacrificial Anode for Water Tank

-

1.Do you provide OEM/ODM service?

A: Yes, OEM/ODM is welcome, we have the professional R&D team.They work for you all the time (design, tooling/mould, sample, mass production).

-

2.How can I know your company further?

A:Please leave message in website with you email or phone number, the sales manager will send the catalogue to you by email or call you directly.Also welcome to visit our company!

-

3.How can I get the quotation, sample, mass production?

A: Please show us the sizes/drawing of the parts you need, our business director will show you detailed quotation with the lead time of sample and mass production.

-

4.How do you control the quality?

A: The products are produced under ISO9001 & SGS certificate.